-

13th August 2019, 04:16 PM

#1

Ultem and CF Peek in an aluminum mold

Hey guys -

New to the forum, molding for a decent amount of time...

Recently took a new position at a mainly CNC shop that purchased two brand new JSW 180 ton machines and all supporting equipment. Their general idea was to near net mold and save time and waste material.

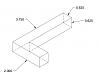

Seemed reasonable... They have an initial aluminum mold, two cavities, "L" shaped parts. Dimensions of each part are 3.75 x 2.0 x .625

They wanted me to sample a wide range of material from ABS, to GF Nylon, various Ultem grades and today, they gave me PEEK 450G and GF PEEK.

They have oil to get the mold temp up, but it's an aluminum base... Am I crazy, or is this a waste of time and going to turn out poorly?

Any input is appreciated.

-

14th August 2019, 01:31 PM

#2

Re: Ultem and CF Peek in an aluminum mold

I’ve found it easiest to place heaters in the mold base and use a mold heat controller to get the mold hot enough. Place rod heaters with thermocouples in the mold to get it hit enough. Also add an insulating board to get it to heat faster and not have to heat plattens.

Make sure the ejector (pins) were ran in steel sleeves. This will stop mold base wear and extended repair times. If the sleeve galls up just replace them both. Make sure gate areas are hard inserts to improve replacement timing of worn parts. Also you may need place a hard insert opposite the gate for wear too. The mold can be DLC coated to slow wear of the base material.

rick.

-

14th August 2019, 07:26 PM

#3

Re: Ultem and CF Peek in an aluminum mold

After giving them feedback, they're in full understanding of what to expect with this mold and are completely happy to replace with a steel version if we can mold the parts.

Thanks for the insight Rick.

-

14th August 2019, 11:42 PM

#4

Re: Ultem and CF Peek in an aluminum mold

Rick:

Have you been happy with the DLC you've used? Also which plater(s) have you used for this?

-

16th August 2019, 06:15 AM

#5

Re: Ultem and CF Peek in an aluminum mold

Nikom,

We have looked at it for SEVERAL molds. But to convince a company to try something new is ALWAYS a stretch. There’s a place in NC reasonably close to us that we want to use. Our thoughts were to do lifters and like ejector pins with slots for ribs cut in them. They used to be Sulzer but I think the parent company made a push to adopt their name.

They brought in plated guide pins and round bushings for a mold. Ridiculous how slick they are w/o lube on them. I’ve seen molds Dynablued for glass wear resistance but hard to repair some damage. With DLC I think they can remove, repair and plate again.

Rick

-

20th August 2019, 08:51 PM

#6

Re: Ultem and CF Peek in an aluminum mold

My biggest sturggle has been making the parts without voids in the middle... I'm tried everything. The mold is 350 degrees, the material is at 735 degrees. Slow speed, high speed, low BP - high BP, High pressure, low pressure, short cool times, extended cool times....

I'm near the point of just saying that I don't think we can mold a part that's as thick as this is without the voids...

Any last suggestions?

Currently the part is filling through a runner in the middle of the "L" shape... I'm contemplating having dual fill spots? Near the top and bottom? Or will that do nothing?

-

21st August 2019, 02:24 AM

#7

Re: Ultem and CF Peek in an aluminum mold

What is the thickness of the part? What size and shape are the gates and runners/sprue?

I'm hoping that only one of the 0.625 dimensions in this sketch is correct and your part has a much thinner wall.

Posting Permissions

Posting Permissions

- You may not post new threads

- You may not post replies

- You may not post attachments

- You may not edit your posts

-

Forum Rules

Reply With Quote

Reply With Quote