-

14th August 2019, 11:42 PM

#1

Re: Ultem and CF Peek in an aluminum mold

Rick:

Have you been happy with the DLC you've used? Also which plater(s) have you used for this?

-

16th August 2019, 06:15 AM

#2

Re: Ultem and CF Peek in an aluminum mold

Nikom,

We have looked at it for SEVERAL molds. But to convince a company to try something new is ALWAYS a stretch. There’s a place in NC reasonably close to us that we want to use. Our thoughts were to do lifters and like ejector pins with slots for ribs cut in them. They used to be Sulzer but I think the parent company made a push to adopt their name.

They brought in plated guide pins and round bushings for a mold. Ridiculous how slick they are w/o lube on them. I’ve seen molds Dynablued for glass wear resistance but hard to repair some damage. With DLC I think they can remove, repair and plate again.

Rick

-

20th August 2019, 08:51 PM

#3

Re: Ultem and CF Peek in an aluminum mold

My biggest sturggle has been making the parts without voids in the middle... I'm tried everything. The mold is 350 degrees, the material is at 735 degrees. Slow speed, high speed, low BP - high BP, High pressure, low pressure, short cool times, extended cool times....

I'm near the point of just saying that I don't think we can mold a part that's as thick as this is without the voids...

Any last suggestions?

Currently the part is filling through a runner in the middle of the "L" shape... I'm contemplating having dual fill spots? Near the top and bottom? Or will that do nothing?

-

21st August 2019, 02:24 AM

#4

Re: Ultem and CF Peek in an aluminum mold

What is the thickness of the part? What size and shape are the gates and runners/sprue?

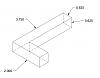

I'm hoping that only one of the 0.625 dimensions in this sketch is correct and your part has a much thinner wall.

-

21st August 2019, 01:55 PM

#5

Re: Ultem and CF Peek in an aluminum mold

I used to mold a PEEK plaque that was around 2.5” x 2.5” x .375”. Mold temp 400 F and – most importantly – the cavity was sprue gated. Cooling time was very long – 60 or 90 seconds. Hold pressure just low enough to not blow the mold open. But as Nikom says, I wouldn’t have much hope of making a good part with a .625” wall section.

As for Ultem, if you’re going to machine the parts so appearance isn’t an issue: if you run the melt and mold very hot so the part cools very slowly, you just might be able to trade voids for sink.

-

21st August 2019, 03:03 PM

#6

Re: Ultem and CF Peek in an aluminum mold

Thanks Jay, yeah these are very thick parts. It makes sense why no company would give them a bid for doing it. Good for me, I have a great job. Bad for me, mission impossible. I'm going to try to add more heat to the mold and open the runner to the normal call out of 75% and spure gate the cavities. Hopefully that helps.

Thanks for the insight all. Will post if I'm successful in my efforts.

-

22nd August 2019, 02:17 AM

#7

Re: Ultem and CF Peek in an aluminum mold

How are you heating the tool? Can you get it hotter? Perhaps the runner is freezing too soon hence the sinks or voids. Can you injection compression the parts? Maybe that would work.

Rick

-

21st August 2019, 03:00 PM

#8

Re: Ultem and CF Peek in an aluminum mold

Unfortunately that is the exact shape and size of the part, only that there are two cavities in the mold. One facing up, the other upside down. Nearly in the shape of a square.

As for the runner and sprue - sprue starts at .275 and opens / tapers to the runner at .400

The runner is circular - undersized at .370 (I say undersized because typical runners are 75% of the part wall thickness - usually)

Posting Permissions

Posting Permissions

- You may not post new threads

- You may not post replies

- You may not post attachments

- You may not edit your posts

-

Forum Rules