|

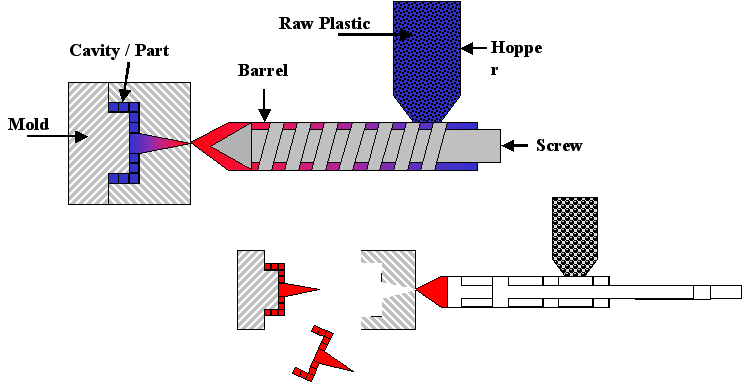

a. What is Injection Molding?

Injection Molding is the technique of injecting molten plastic into a cold

mold and forming a part. A schematic of the main elements of a molding machine

are shown below. It consists of a hopper that holds the raw plastic pellets.

The hopper feeds the barrel with the plastic. The plastic is melted in the

barrel and with the help of the screw (piston) is injected into a mold. The

mold being colder than the plastic rapidly cools and solidifies the plastic.

The mold is then opened and the part is ejected out of the mold.

b. What is the importance of melt viscosity in

Injection Molding?

During Injection Molding, the material is subjected to large amount of

shear forces during the cavity filling stage. The shear rate is proportional to

the injection speed. If the shear rates are in the non-Newtonian region of the

curve, then small variations in the shear rate will cause a large shift in the

viscosity. This will make the mold filling inconsistent resulting in shot to

shot inconsistency. It is therefore important to find the Newtonian region of

the curve and set the injection speed (therefore shear rate) in this region.

The viscosity curve can be generated at the molding machine for any given mold.

The term ‘In-Mold Rheology’ is another term used for developing the viscosity

curve. The effect of shear rate on viscosity is far greater than that of

temperature. Therefore as long as the actual melt temperature is in the within

the recommended range you will get a similar profile during the development.

|